Introduction: Why Ply Differences Matter for B2B Sourcing

For professional kitchen suppliers, retail buyers, and private-label partners, understanding the structural and performance differences between tri-ply and 5-ply stainless steel cookware is essential for making informed sourcing decisions. Both constructions offer premium thermal performance, but they serve distinct market segments and culinary applications. In this guide, we break down the engineering, benefits, and strategic value of each—helping B2B partners select the right product line for their brand positioning and customer needs.

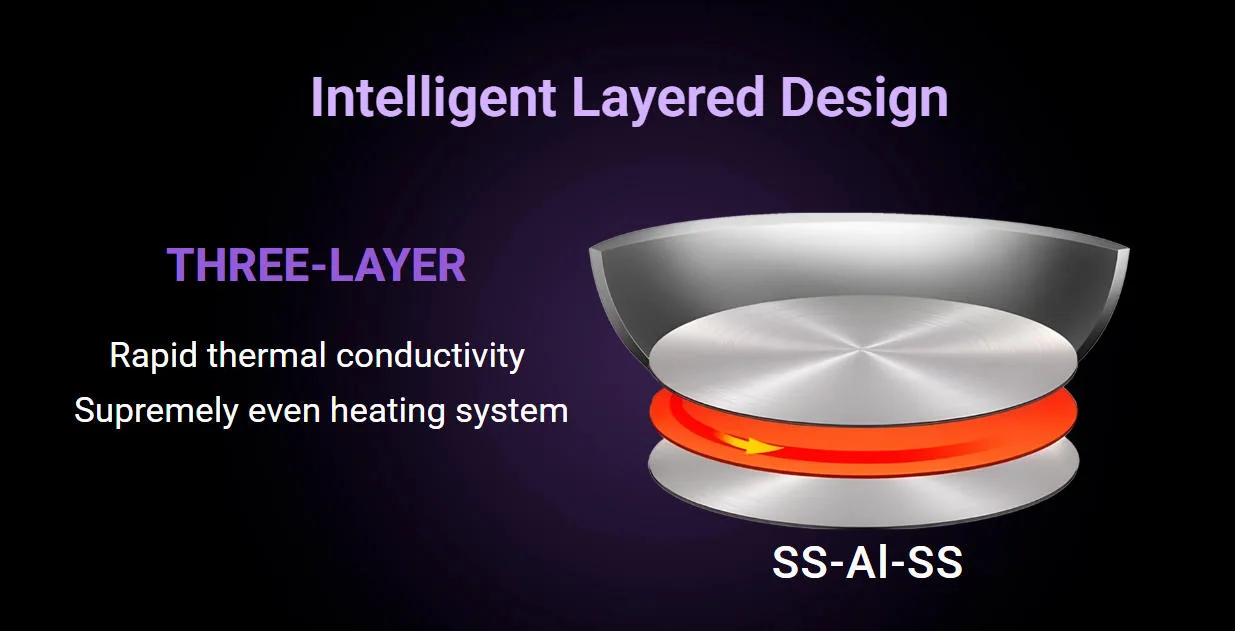

Understanding Ply Construction in Premium Cookware

“Ply” refers to the number of bonded metal layers in a cookware piece. High-performance stainless steel cookware typically features a multi-ply design—usually with aluminum or copper cores—encapsulated between layers of 304 stainless steel. This construction combines the durability and hygiene of stainless steel with the superior heat conductivity of aluminum, delivering even heating and reduced hot spots.

Tri-Ply vs 5-Ply: Core Layer Configurations

- Tri-Ply (3-Ply): Three layers—stainless steel / aluminum / stainless steel

- 5-Ply (Five-Ply): Five alternating layers—stainless / aluminum / stainless / aluminum / stainless

The additional layers in 5-ply enhance thermal mass and heat distribution, making it ideal for precision cooking and high-volume use.

Tri-Ply: The Balanced Choice for Everyday Performance

Tri-ply cookware strikes an optimal balance between performance, cost-efficiency, and weight—making it ideal for mid-to-high-end retail brands and commercial kitchens seeking reliable, everyday durability. With a thick aluminum core sandwiched between two layers of 304 stainless steel, it delivers rapid and even heating across induction, gas, and electric stovetops.

It’s also lighter than 5-ply, which improves handling and reduces fatigue during extended use—important for high-turnover kitchens. For buyers targeting value-conscious yet quality-driven markets, tri-ply offers excellent return on investment without compromising core functionality.

5-Ply: Engineering Excellence for Professional Demands

5-ply cookware represents the pinnacle of thermal engineering in cooking with stainless cookware. With two aluminum layers and three stainless steel layers, it provides superior heat retention, exceptional temperature stability, and near-perfect heat distribution. This makes it ideal for delicate tasks like simmering sauces, searing proteins, or maintaining consistent temperatures in banquet cooking.

The added thermal mass reduces the risk of scorching and allows for energy-efficient cooking—once heated, it maintains temperature with minimal input. For premium brands, hotel chains, or culinary schools, 5-ply signals commitment to excellence and long-term value.

Health, Safety, and Market Positioning

Both tri-ply and 5-ply constructions use food-grade 304 stainless steel, ensuring non-reactive surfaces that won’t leach metals or alter food chemistry. This makes them among the most healthy cookware options available—free from PFOA, PTFE, and other synthetic coatings.

For buyers in health-conscious markets—such as organic retailers, wellness resorts, or eco-living brands—this non-toxic profile enhances brand credibility and aligns with clean-label trends.

Selecting the Best Stainless Steel Frypan for Your Line

When curating a collection, consider the best stainless steel frypan based on target use:

- For fast-paced commercial environments (e.g., diners, casual chains): A tri-ply 12-inch frypan offers agility, fast heat response, and ease of handling.

- For luxury retail or professional kitchens (e.g., fine-dining, culinary academies): A 5-ply frypan with reinforced welding and precision-tapered edges delivers unmatched searing performance and long-term durability.

Conclusion: Matching Performance to Market Needs

Tri-ply and 5-ply are not competing technologies—they are complementary solutions for different market tiers. Whether you’re building an accessible premium line (tri-ply) or a top-tier professional collection (5-ply), understanding these differences empowers smarter sourcing decisions.

Partner with us to deliver performance, safety, and innovation—engineered for your B2B success.